Brightening Series: The Complete Guide

Stamping parts are a core element of modern manufacturing. From automobiles to electronics, these parts help shape metal into precise forms at high speed and low cost. Because of their strength, accuracy, and scalability, stamping parts are widely used across many industries. Below is a complete, easy-to-read guide that explains stamping parts in detail, following a smooth content flow with clear sections.

What Is a Stamping Part?

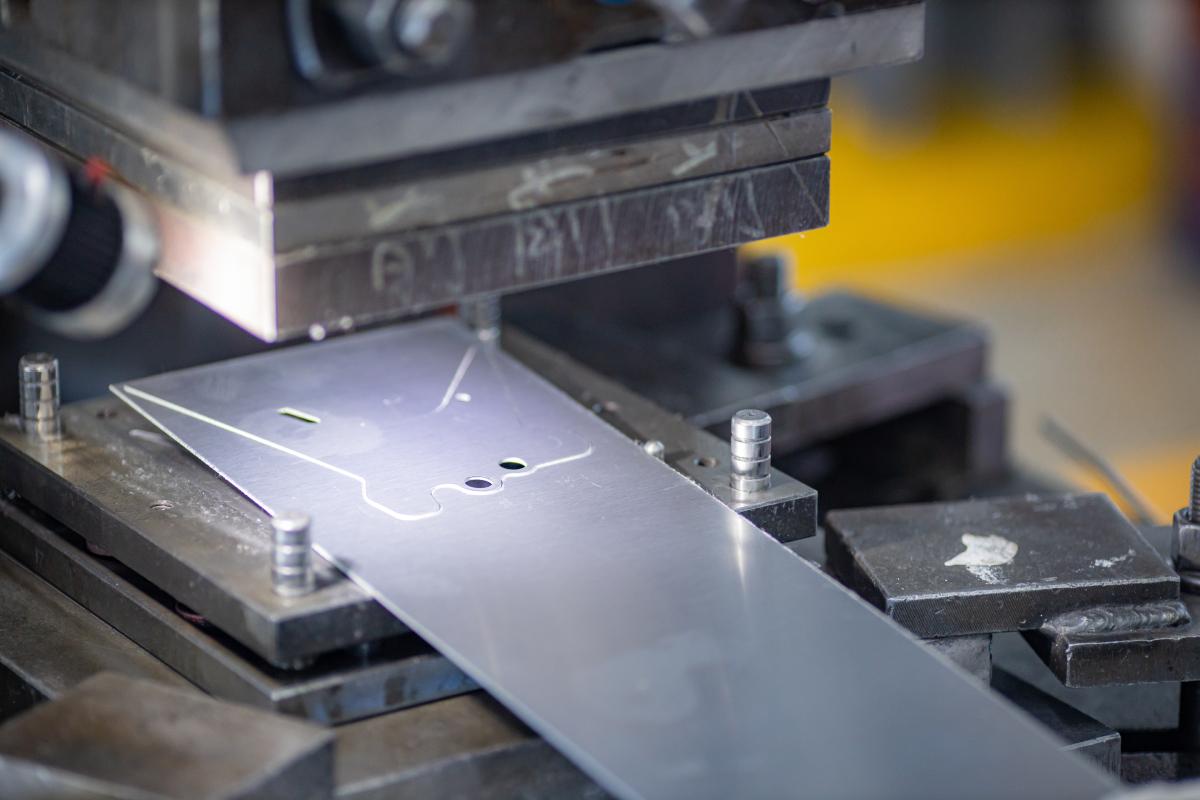

A stamping part is a metal component produced by shaping flat metal sheets using a press and a die. The process applies pressure to cut, bend, or form the metal into a desired shape. This method is popular because it allows mass production with consistent quality.

Stamping parts are usually made from steel, aluminum, brass, copper, or stainless steel. These materials are chosen based on strength, flexibility, corrosion resistance, and cost. Due to tight tolerances, stamping parts are ideal for industries that require accuracy and repeatability.

Types of Metal Stamping Parts

There are several types of stamping parts, each created for a specific function. Blank parts are cut from a metal sheet without forming. Bending parts are shaped at angles to fit assemblies. Deep-drawn parts are formed into cup-like or hollow shapes. Progressive stamping parts are produced through multiple steps in a single press cycle.

Each type serves a different purpose, but all share the same goal: fast production with minimal waste. Manufacturers often combine multiple stamping techniques to reduce cost and improve efficiency.

Stamping Part Manufacturing Process

The stamping process starts with placing a metal sheet into a stamping press. A die then presses the sheet into shape using controlled force. Depending on the design, the process may include cutting, punching, bending, or forming.

After stamping, parts may go through secondary processes such as deburring, polishing, heat treatment, or surface coating. Many factories follow quality systems like ISO 9001 to ensure consistency and reliability. This structured process helps deliver parts that meet strict industry standards.

Materials Commonly Used in Stamping Parts

Material selection is a key factor in stamping part performance. Steel is widely used because of its strength and low cost. Aluminum is lighter and resistant to corrosion, making it ideal for transport and electronics. Copper and brass offer excellent conductivity, which is why they are common in electrical parts.

Stainless steel is chosen when durability and corrosion resistance are critical. Each material reacts differently under pressure, so manufacturers carefully match materials with die design and press capacity.

Industries That Use Stamping Parts

Stamping parts are used in many industries. The automotive sector relies heavily on stamped components for body panels, brackets, and structural parts. Global brands like Toyota and Ford use stamping parts to ensure uniform quality in large-scale production.

Electronics manufacturers use stamping parts for connectors, shields, and frames. The construction industry depends on stamped brackets and fasteners. Even household appliances and medical devices use stamping parts because of their precision and strength.

Advantages of Using Stamping Parts

One major advantage of stamping parts is cost efficiency. Once the die is created, large volumes can be produced quickly with low per-unit cost. The process also offers high accuracy, which reduces the need for extra machining.

Stamping parts are strong, durable, and consistent. They also generate less material waste compared to other manufacturing methods. Because of these benefits, stamping is ideal for both simple and complex designs.

Quality Control and Design Considerations

Good stamping parts start with smart design. Engineers must consider material thickness, bend radius, and tolerance. A well-designed die ensures smooth production and long tool life.

Quality control includes dimensional checks, surface inspection, and functional testing. Many manufacturers apply coatings or plating to improve corrosion resistance and appearance. By focusing on quality from design to delivery, stamping parts perform better and last longer.

Future Trends in Stamping Parts

The future of stamping parts is moving toward automation and smart manufacturing. Advanced presses now use sensors and real-time monitoring to improve accuracy and reduce downtime. Lightweight materials and eco-friendly processes are also gaining attention.

As industries demand higher precision and sustainability, stamping technology continues to evolve. This ensures stamping parts remain a reliable and essential solution for modern manufacturing needs.

Conclusion

Stamping parts play a vital role in today’s industrial world. They offer speed, precision, strength, and cost efficiency across many applications. From automotive and electronics to construction and appliances, stamping parts support mass production without compromising quality.